Description

PRODUCT BENEFITS

Straightforward installation and easy cutting to length

- installation of windows of small to medium size in the insulation level

- extensive individual tests by testing institutes**

- optimum integration in thermal insulation composite systems

- airtight connection to the masonry

- optimisation of the Ψ-value thanks to highly heat-insulating insulating profiles

- complies with the requirements of the Building Energy Act (EnEV was valid 31.10.20)and the recommendations of the RAL “installation guide”

- the ideal basis for 3-level-sealing with multi-functional joint sealing strips

- excellent for energy-related building renovation

- can be combined with the IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER “TYPE 1”

- 10-Year Function Warranty*

* On the conditions of the manufacturer (available on request)

** In-front-of-wall installation systems are currently not subject to any regulation by the DIBt. Approvals such as aBG or abZ must therefore be covered by individual tests. Details on approval as in front of wall installation system for building projects must be obtained individually from the responsible planning office.

APPLICATION AREAS

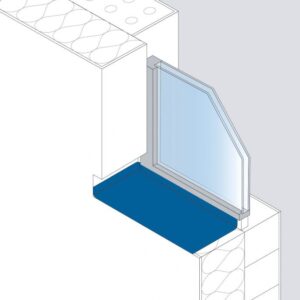

Combination of conventional console installation and in-front-of-wall installation frame

The IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER “TYPE 2” is especially suitable for the installation of small to medium-sized windows up to 2 m². Due to the low window weights, the load transfer only takes place at the lower connection area, where the ISO-TOP WINFRAMER SYSTEM BRACKET “TYPE 2″ has ISO-TOP FLEX-ADHESIVE WF applied and is then glued to the masonry. The system bracket is not only glued airtight but also fixed in place on the masonry using attachment screws.

As with conventional console installation, the window installation is usually carried out using aluminium attachment consoles fixed at the sides. The consoles are then covered with the highly thermally insulating profile and thermally decoupled. The individual insulating profiles are glued to the masonry, ensuring an air-tight insulating layer all the way around and a completely thermally decoupled window area. Once finished, this window frame creates an optimum precondition for load transfer and offers an ideal installation level for installation and sealing according to the specifications of the RAL” installation guide”.

Efficient and simple installation

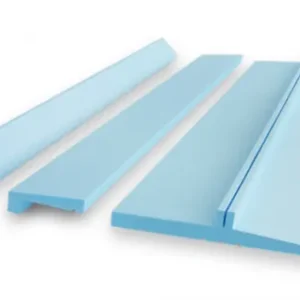

The insulating profiles can be cut to the required length using a knife or so-called “hot blade”. This allows residual pieces to be used efficiently as well, thus saving costs. The dovetail connection of the insulating profiles helps during installation and makes much easier handling and a clean and technically perfect connection to the masonry possible.

After window installation, the IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER “TYPE 2” can be covered directly by a thermal insulation composite system.