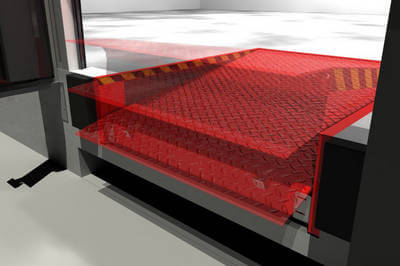

The dock leveller compensates for the height difference between the dock and the cargo floor.

The RH12B dock leveller is an electrohydraulic dock leveller with a swing lip. The installation of the dock leveller and the preparation of the dock pit are very simple, as this model features a self-supporting design. The dock dimensions and the installation method were designed so as to enable its installation in standard prefabricated dock pits with an undercut to accommodate the tail lift.

Dock seals supplied by WISNIOWSKI are great solutions, which provide durability and good operational properties. They make it possible to limit energy consumption and ensure protection for unloaded and loaded goods, while at the same time providing comfortable working conditions for the personnel.

Thanks to the use of durable materials, they are highly resistant to UV radiation, as well as high and low temperatures. They retain a lasting appealing look and individual elements are not prone to deformation.

We offer dock seals in different versions adapted to the type of vehicle, unloaded and reloaded goods, and storage methods.

Safe and accurate docking of a lorry in the loading dock is possible thanks to the use of wheel guides.

The wheel guides enable the vehicle to park accurately without the risk of damaging the loading dock, the building or the vehicle

Provide additional protection to prevent loading dock and vehicle damage. They absorb the force and impact of the lorry trailer backing up to the loading dock.

Design

The 2,000×2,560 [mm] RH12B is an electrohydraulic dock leveller with a swing lip. The installation of the dock leveller and the preparation of the dock pit are very simple, as this model features a self-supporting design. The dock dimensions and the installation method were designed so as to enable its installation in standard prefabricated dock pits with an undercut to accommodate the tail lift. The installation width of the dock pit for installing the dock leveller is 2,060-2,085 [mm]. The deck is moved with two hydraulic actuators (the swing lip is moved by a separate actuator). The deck is made of sheet 8 [mm] thick, swing lip 15 [mm] thick, grade S235JR. The dock leveller is provided with longitudinal and lateral reinforcement made of high-strength, grade S355NL steel. The rear part of the deck is attached with three hinges.

Operation

The dock leveller is operated with a single button. When the button is pressed, the deck is lifted from the home position and the lip is extended when the highest position is reached. When the button is released, the deck is automatically lowered until the swing lip rests on the vehicle cargo floor.

Safety features

Technical specification

| Capacity (EN 1398) | 60 kN |

| Installation height | 600 [mm] |

| Lip length | 400 [mm] |

| Lip angle (from the end face) | (ca. 5O) 150 [mm] |

| Motor | 0,75 kW |

| Diameter of main actuator piston rods (2 pcs.) | 35 [mm] |

| Diameter of the lip actuator piston rod | 30 [mm] |

| Ambient temperature operating range | from -30OC to +40OC |

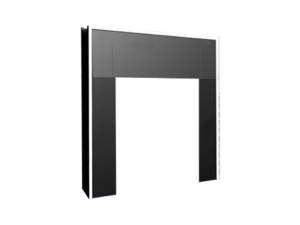

Design

The 3,400×3,400 [mm] ABRE dock shelter can be used with docked lorry widths of 2,300-2,500 [mm] and heights of 3,600-4,200 [mm].

The front and rear frame is made of galvanized steel sections connected with elastic adjustable arms. The integrated incline in the top part ensures proper rainwater drainage. The canvas is made of two-layer reinforced polyester material, covered with 3 [mm] thick PVC, with the basis weight of 3,200 [g/m2], with high tear and friction resistance. Side canvases are printed with stripes, which act as guiding marks.

Technical specification

| Width | 3400 [mm] |

| Height | 3400 [mm] |

| Installation depth | 600 [mm] |

| Width of the side canvases | 600 [mm] |

| Height of the top canvas | 1000 [mm] |

| Front canvas basis weight | 3200 g/m2 |

| Standard colour | RAL 9005 (black) |

Design

The 3,500×3,700 [mm] ABRE dock shelter can be used with lorry widths of 2,400-2,800 [mm] and heights of 3,600-4,200 [mm]. The cushions are made of a high-strength PVC material with M2 fire resistance. Protective strips made of a two-layer elastic polyester material with the basis weight of 3,200 [g/m2]. A strong, friction resistant, antistatic PVC layer is provided on both sides.

The side and top structure comprises layered panels with a thickness of 40 [mm], with a white RAL 9002 exterior and interior. Due to safety considerations, the dock shelter is fitted with protective brackets.

Technical specification

| Width | 3500 [mm] |

| Height | 3700 [mm] |

| Installation depth | 1000 [mm] |

| Installation height (recommended) | 4800 [mm] |

| Front cushion canvas (basis weight) | 900 g/m2 |

| Top cushion canvas (basis weight) | 500 g/m2 |

| Width of the side cushions (inflated) | 650 [mm] |

| Depth of the top cushion (inflated) | 1200 [mm] |

| Control panel protection rating | IP55 |

| Power supply | 230V / 0,30 kW |

| Control voltage | 12V DC |

| Operating temperature | from –20OC to +70OC |

| Colour | RAL 9005 (black) |

Symmetric wheel guides (right and left can be used interchangeably). Made of a hot-dip galvanized tube with a 140 [mm] diameter.

Available versions:

Technical specification

| Length | 2620 [mm] |

| Height | 260 [mm] |

| Diameter | 140[mm] |

| Thickness | 3[mm] |

| Material | Galvanized steel grade SP44 |

| Number of feet | 3 |

The bumpers are made entirely from a rubber cast, dimensions 250x500x90 [mm].

In order to ensure maximum product durability, the bumpers are supplied with a 10 [mm] thick mounting plate

Technical specification

| Thickness of the steel mounting plate | 10 [mm] |

| Rubber thickness | 70 – 80O Shore |

| Rubber density | 1,24 g/cm2 |

| Rubber elasticity | 30% |

| Breaking strength | 129,6 g/cm2 |

help@factorymarket.online

Parnu Savi 3/2 80040

Design & Developed by Techsaga Corporations.